Inventing New Materials

Students of Indian Institute of of Space Science and Technology launched an actual rocket while still in college—nobody has since. After a stint in ISRO, they wondered if they could replace steel.

"Why are we carrying 200 kg passengers in 2000 kg cars?"

In early 2021, Gagan Agarwal and Prakhar Agarwal, both ex-ISRO Rocket Scientists, sat across from their mentor, Sunand Sharma, the former chairman of Alstom South Asia, when Mr Sunand asked them this question.

They began to wonder. Gagan says:

"So many industries have lightweighted. Rockets, planes, boats, racing cars, turbines—we've lightweighted everything. Why can't we do automobiles?"

"Why are automotives still stuck with steel? We haven't changed it much over the last 100 years," he observes.

While at one end of the paradox, you have a situation where steel is ‘perceived’ to be stronger and safer by the general public, the other end of the paradox is the narrative that we want to control carbon emissions and ‘save the planet’.

Gagan says:

"We all talk about going electric and sustainability. But what about the dead mass you've been carrying all along, wasting diesel and battery."

Could you replace steel with a better material? Is that even a question worth daring to ask? Gagan and Prakhar were curious—and they got to work.

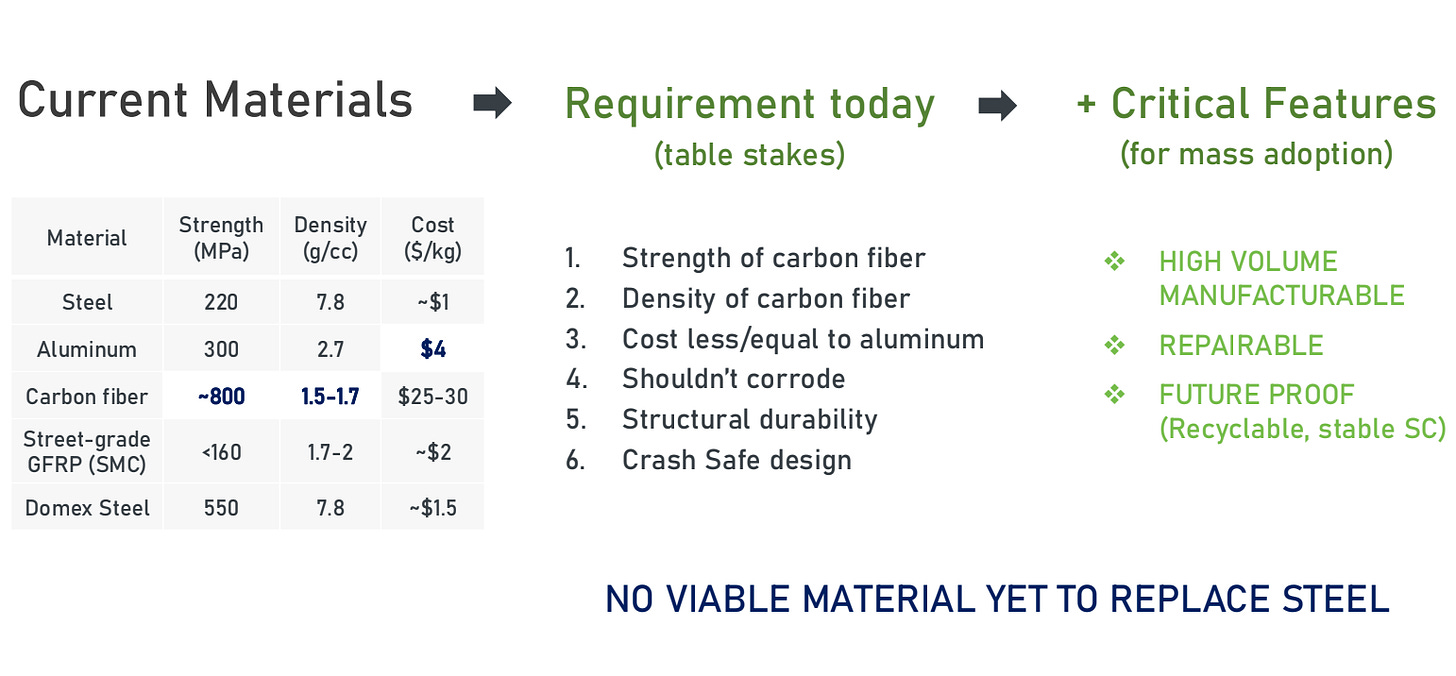

But replacing steel isn't just about finding lighter materials—it requires solving multiple constraints simultaneously. Gagan explains:

"A structure needs to take the vertical weight of the cargo. It needs to handle all dynamic loading from roads, whether potholes or bumps. It needs to manage acceleration and braking loads. Nothing should fail for 12-15 years minimum. You need crash safety—the person sitting in front during a crash needs to be safe."

Four years later:

This raw footage doesn’t have audio, but you get to see how a vehicle made with Planet’s Silica Composite looks.

The Tata Ace EV has a kerb weight of 1,240 kg and offers a 600 kg payload capacity, while Planet Electric's version managed to achieve a kerb weight of 720 kg and a 750 kg payload capacity.

This by itself is remarkable.

But before we explain what Planet’s Silica Composite is, let us explain who the people are who invented it.

The Heritage of India’s Missile Man

For Prakhar, growing up in Lucknow, the inspiration came early.

"I was in 3rd or 4th class in 1993 and I saw the PSLV launch. That's when it was clear to me that I would be a rocket scientist."

Gagan's path was more philosophical.

"I was always thinking about the concept of time. I did not like that time was infinite. I got into astrophysics, cosmology, star formation, big bang—everything. I had no doubts that I wanted to study something to do with space technology."

Both qualified for IIST through the JEE, joining an elite cohort — Prakhar was in the first-ever batch of the newly established IIST in 2007, while Gagan joined in the second batch the next year.

With just 150 students per batch and direct placement into ISRO upon graduation, it was an unprecedented opportunity.

"He gave us lectures, he interacted with us. We received our degrees from him," Prakhar recalls.

Gagan adds, "You get a sense of humility once you see him in person. I have not seen anyone as humble as him."

What was Dr Kalam’s key lesson to them?

Gagan says, "He told us to think in generations and be ambitious. And that is exactly what we did."

Prakhar and Gagan decided to do just that. They decided to build and launch an actual rocket while still in college.

No group of students in India had done it before, and nobody has since. The group led by Gagan and Prakhar has been the only one to date.

"Basically, a bunch of us wanted to build a rocket and fly," Gagan explains.

"We had no idea how to do it. We didn't know how small it would be, but somehow we wanted to make a professional rocket."

Wikipedia:

VYOM ('sky' in Sanskrit) is the sounding rocket designed by the BTech students of IIST. Vyom had its maiden flight on 11 May 2012 when it took to the sky from TERLS and the mission was a success. The objective of the launch was to flight-test the solid rocket motor and the accelerometer payload developed for the project. Vyom is the first student made sounding rocket in Asia.

The project required true systems engineering across multiple disciplines. With unprecedented access to VSSC through their director, they dove into decades of rocket science knowledge.

"We used to go to VSSC libraries. I have read NACA articles — when NASA was NACA—since 1932. We read in the first year what we would typically learn in the third year, just because we wanted to build a rocket."

After navigating 153 range clearances, their rocket launched on May 11, 2012, reaching 16 kilometers into the stratosphere.

"Commercial airliners fly at 10 kilometers. Although we weren’t suborbital, but we were very proud. It is higher than Mount Everest—double."

"We were the first ones to do it in Asia," Prakhar notes with justifiable pride.

After graduation, both entered ISRO's professional ranks. Gagan joined the Reusable Launch Vehicle project, India's space shuttle program.

"I worked on reusable launch vehicles for three years. We had to fly above Mach 5, re-enter, and land. Much harder challenge than our college project."

Prakhar spent a decade in composites and structural engineering, gaining comprehensive experience.

"Right from the beginning till the end. I got the opportunity to look at the entire detailed life cycle. Not just 'I've designed it, done, my role is over.' I had to look into every detail."

In 2021, they founded Planet.

Problem Statements

"We invent new materials using space technology to secure the future of our species," says Gagan.

It's an audacious claim that would sound woozy coming from anyone, but strangely, totally believable coming from two former ISRO scientists who have spent the last four years developing composite materials that could fundamentally transform the automotive industry.

Beyond material properties, manufacturing presented its challenges.

Traditional composites manufacturing takes hours per part—acceptable for aerospace, where volume is low, but impossible for automotive scale.

"If they need high strength, typically it takes 4 hours per part. Why? Because they were made for aerospace. No one managed to recalibrate the manufacturing process according to high volume," Gagan explains.

And then there is the challenge of safety. The crash safety standards are particularly demanding:

"The typical norm is to make a crumple zone. About 400mm will be crushed in 700 milliseconds with resultant G-force between 24-32G on the passenger's neck. This is NCAP 4 rating."

Previous attempts with aluminum failed on multiple fronts.

"Aluminum has two or three major problems. Number one, cost—it's typically $4 per kg versus steel at less than $1."

Carbon fiber, while strong, is prohibitively expensive.

"CFRP (Carbon Fiber) is 25-30 times more expensive than steel. It's out of the question. Even glass fiber reinforced plastic (FRP), commonly used in industrial applications, lacks the strength for automotive structures."

Planet’s Silica Composite

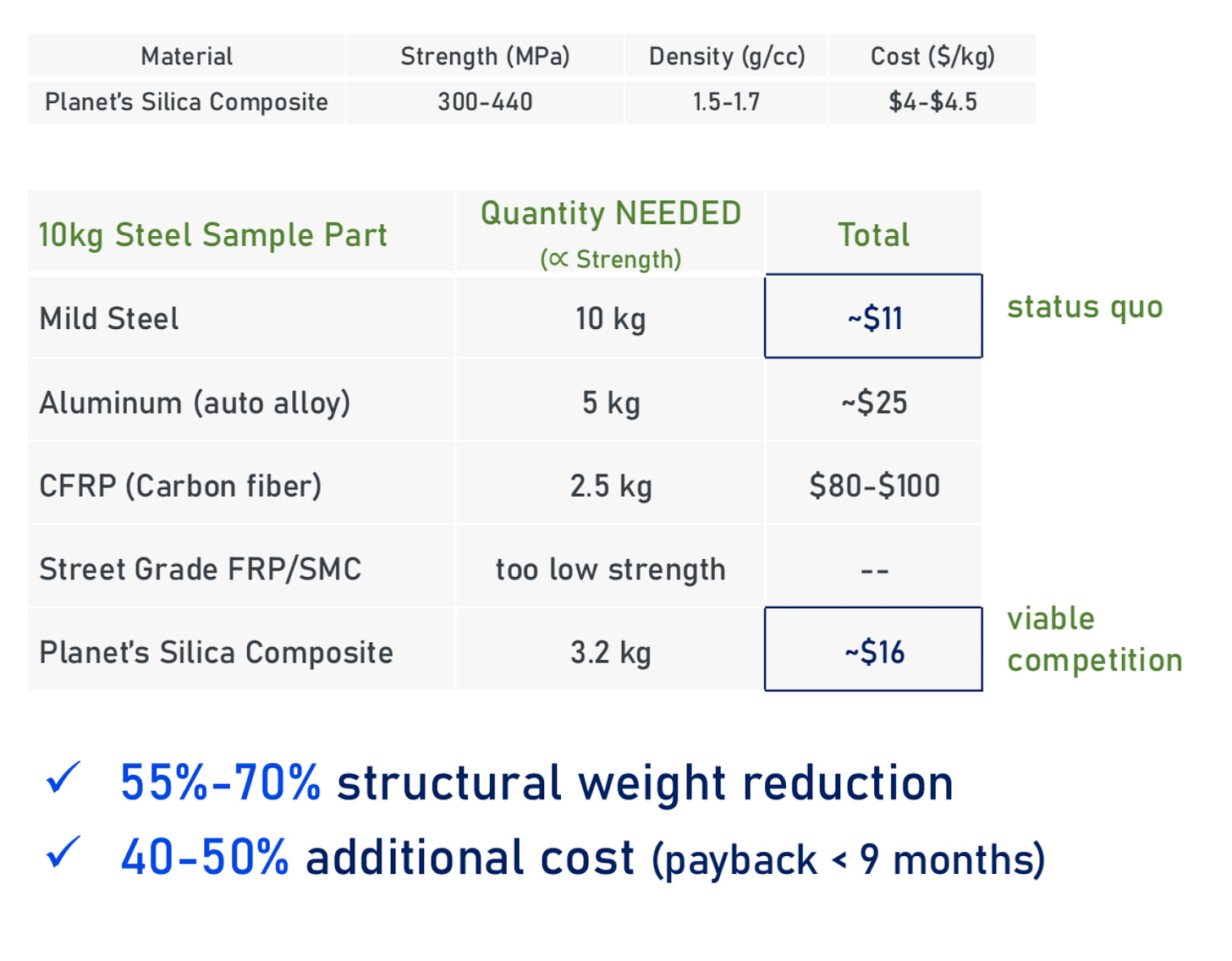

The technical innovation centers on what they call "silica composites"—E-glass fiber combined with specific resins and fillers.

"A composite is basically two or more materials combined. Metal has micrometer-level defects. To cure that, we bond fiber and resin so the strength increases automatically."

But creating automotive-grade composites required solving the manufacturing equation.

"We looked at 12 manufacturing processes prevalent in aerospace. None would work. But then we understood there are other manufacturing processes we can learn from."

They studied compression molding used for electrical insulation panels and pultruded beams for cooling towers.

"We took compression molding machines, went from 100 tons to 3000 tons pressure. We heated the material to 210-250 degrees. After heating, compression, and curing, we achieved properties that were never achieved from these fiber materials."

The breakthrough wasn't just material composition but manufacturing speed.

"After a lot of heating, compression, and curing, we were able to achieve those properties in 5 minutes instead of 4 hours."

Gagan and Prakhar explain:

"Our ‘right to exist’ is this: replace steel in vehicles with advanced composite materials that are 75% lighter while maintaining superior strength. Our US patent pending silica composites have a flexural strength of 440 MPa—double that of steel's 220 MPa—while weighing just 1.7 grams per cubic centimeter compared to steel's 7.8 grams."

Manufacturing was only half the challenge. Integration into existing automotive systems required a strategic constraint.

"The most important thing we said: we won't change anything. The axle, wheel, steering, motor, battery—everything should be the same. You can't change the supply chain. You are changing the structure."

This limitation became an advantage, allowing integration into existing automotive ecosystems without wholesale changes. But it required solving connection problems. The design philosophy leveraged composites' directional strength properties.

"There is no welding. We use composite-metal joints, adhesives and rivets. These are processes usually done in aerospace that we're adapting for automobiles."

"These materials are fibers. You give strength in the direction you want and remove material where you don't need strength. This is precise engineering that enables almost 75% weight reduction."

Their approach to scaling reflects their engineering background—staged and systematic.

"Prototype—>on-ramp—>scale. Prototype is our design technology. We have reached this stage. On-ramp, we will invest Rs 7-10 crores and put up a small facility in Gurgaon for 1000 boxes per month."

"No one knows composite handling well enough, so we can't afford to compromise on quality. Even OEMs don't have this expertise. For the first 2 years, we need to maintain the highest quality standards."

"This is my proof to the industry that we can do this, customers have accepted it, we can scale, and we can give all of this to suppliers to go to 10,000 boxes."

"We have filed two patents covering design and integration procedues. We will also patent a one-min manufacturing process soon."

"Material formulation we have not disclosed as they are our trade secrets."

This creates defensive moats while enabling licensing opportunities.

"In the long run, everything will be outsourced to suppliers and outside partners who we will train and vet. We will certify them, do R&D, and license technology. We will not manufacture everything ourselves."

"These are not just better materials," Gagan explains.

"We're talking about reducing vehicle weight by 40%, cutting battery consumption by 25%, and enabling 7% diesel savings per vehicle per month."

Finding the right investors

The curse of being a pure technology founder in India is that you have to grow despite the system and not because of it. Case in point is the following email from a respectable fund in India, an offshoot of a well-known publicly listed financial services outfit.

As luck would have it, Gagan and Prakhar found the right partnership through an angel who introduced them to Mirik Gogri.

Planet has raised a seed round of Rs. 6.5 crores, led by Mirik, which allowed the company to carry out its R&D and reach this stage.

Investors who are also entrepreneurs tend to seek absolute returns, not IRR. This allows them to fund businesses with longer development cycles.

Gagan comments:

"Mirik understood the technology from first principles. He knows that this has been done successfully in aircraft. And he knows that someone will do this eventually in automobiles."

Mirik commented:

"We like the fact that they've shown tremendous grit. They've also shown tremendous flexibility. While they have a product, there are different business ideas that they have played with. They have been open to taking feedback and trying to mold to that feedback to see what's the best journey for the company to take."

As part of tal64 reseach’s work, we did our own testing! Here is how it went:

In the first 5 seconds, a drop test on Steel is shown, in the next few seconds, a drop test on Planet’s Silica Composite.

Customer Development and Market Entry

Rather than building in isolation, they adopted a customer-driven approach.

"I said I won't make it generically. I need a customer. The customer will tell me what to make."

The first customer conversation was telling.

"He said, 'My vehicles have poor gradeability, they take too much battery.' We worked for 3 months, came back with simulated results. He gave us the first 1000 pre-orders."

Their go-to-market strategy targeted commercial vehicles first.

"Delivery vans are much better than passenger cars because you don't have charging infrastructure issues—charging happens at hubs, routes are fixed. I can go to the biggest logistics customer and ask how much will you buy? 500 trucks, 1000 trucks?"

"Steel containers weigh 330kg, ours weigh 130kg—200kg saved. In the same fuel consumption, they can carry 200kg extra payload. If you reduce 200kg, you use 7% less diesel."

For electric vehicles, the benefits compound.

"We reduce battery consumption by 25%. That's 25% upfront battery cost savings and lifetime 25% charging cost reduction."

The company has already built functional prototypes for its cargo boxes and signed MOUs worth $7 million specifically for cargo boxes made with Planet’s Silica Composite, and attracted pre-orders from 33 customers spanning logistics giants, OEMs, and new mobility companies.

For example:

"About 43% of our operating budget is diesel costs. A 6-7% diesel savings almost doubles our net profit margin."

— Sachin Haritash, Director, Chetak Logistics

As of early 2025, Planet Electric is moving from prototype to production.

"Within 4 weeks, these are the 2 big customers who will do certification. The cargo boxes' LOIs are committed though not yet signed."

The customer pipeline is substantial:

"<Name redacted> wants 250 boxes per month, <Name redacted> 150 per month, <Name redacted> 100 per month initially scaling to 200. Then we have larger containers for companies like <Name redacted> and <Name redacted>."

"We need a plant for cargo boxes. That's why we're raising capital."

Capital Raise

Current capital requirements are specific and staged.

"We need Rs 13 crores approx for the on-ramp facility, but we will probably need Rs 25-30 crores in total because hardware always has unforeseen costs. Everyone in the hardware space always says double or triple whatever you initially estimate."

The addressable market is immense: automotive structures alone represent a $500 billion global opportunity, while applications span construction, aerospace, marine, and infrastructure sectors where lightweight, non-corrosive materials could revolutionize performance and longevity.

But Planet Electric's ambitions extend far beyond automotive applications.

Gagan notes:

"Anything that moves or anything that corrodes is our market. Materials that corrode significantly reduce product lifespan—these composite materials will work exceptionally well in those applications."

Success in cargo boxes opens multiple expansion paths.

"I can now go to vehicles, bus bodies, shipping containers—so many other things, where I will only do design and technology, not on-scale manufacturing necessarily."

The business model evolution is clear.

"This business gives you guaranteed revenue—you make it. For larger applications, you become a technology partner. We'll control the supply chain and license the technology."

Their long-term vision, though, extends far beyond automotive.

But perhaps most importantly, they see Planet as proving a model for space-to-earth technology transfer.

"Space technology can be used to solve cost problems in multiple industries. Efficiency directly translates into cost savings."

Planet is raising capital to go from prototyping to production. The company is raising $4 million with Mirik Gogri (mentioned above) continuing to participate.

If you want to talk more about the investment opportunity, reach out to us at banjan@tal64.com for more details.